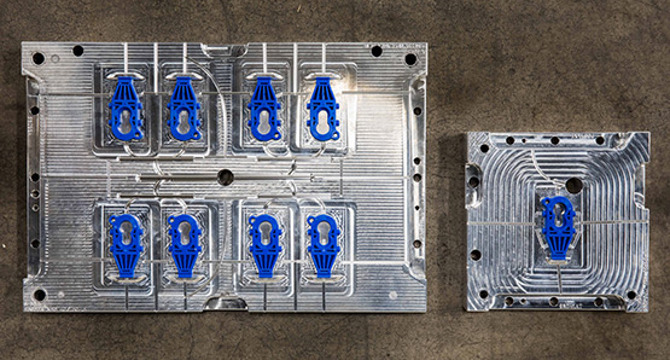

High Pressure Die Casting Mold: A Key to Precision Manufacturing

High pressure die casting mold technology is an essential component in modern manufacturing, enabling the mass production of intricate and high-quality metal components. This casting method is widely utilized in industries such as automotive, aerospace, electronics, and consumer goods, where precision, durability, and efficiency are paramount. The process involves injecting molten metal, often aluminum, magnesium, […]

High Pressure Die Casting Mold: A Key to Precision Manufacturing Read More »